Sed ultrices nisl velit eu ornare

Ut ultricies imperdiet sodales. Aliquam fringilla aliquam ex sit amet elementum dui in fringilla sollicitudin.

Sed enim metus, tempus elementum dui in, fringilla sollicitudin erat. Suspendisse blandit, nisl ut aliquet varius, sem dolor auctor nisi, vel facilisis sapien elit et magna.

Aliquam ac dui vel dui vulputate consectetur. Mauris accumsan, massa non consectetur libero.

95%

Duis dignissim mi ut laoreet mollis. Nunc id tellus finibus nisl ut aliquet varius.

3490

Mauris rhoncus orci in imperdiet placerat. Vestibulum euismod nisl.

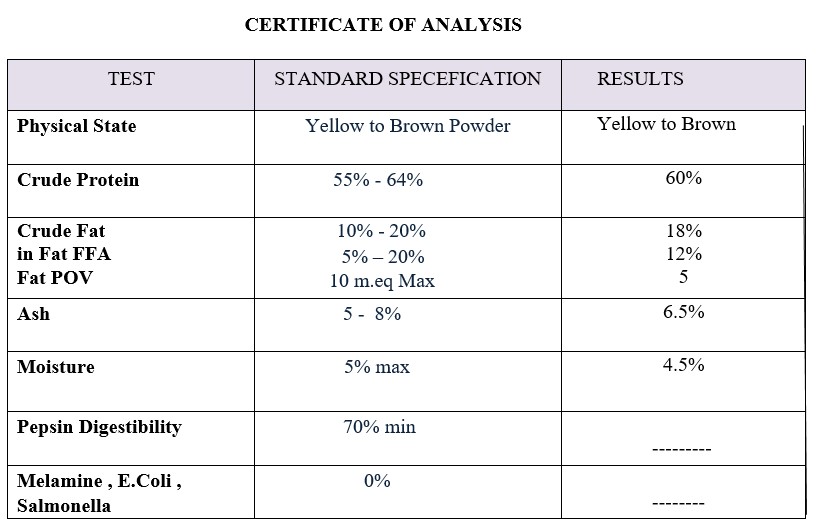

Poultry Protein Meal

It is the dry rendered product from a combination of clean chicken flesh and skin with accompanying bone, derived from whole carcasses of chicken, Intestine, heads, feet & underdeveloped eggs exclusive of feathers, except in such trace amounts as might occur unavoidably in good manufacturing practices. Meal here is used in the sense of an ingredient which has been ground or otherwise reduced in particle size. It is used only in Animal Feed/Pet food.

To create Poultry protein meal, ingredients are placed into large vats and cooked. This rendering process not only separates fat and removes water to create a concentrated protein product, it also kills bacteria, viruses, parasites and other organisms.

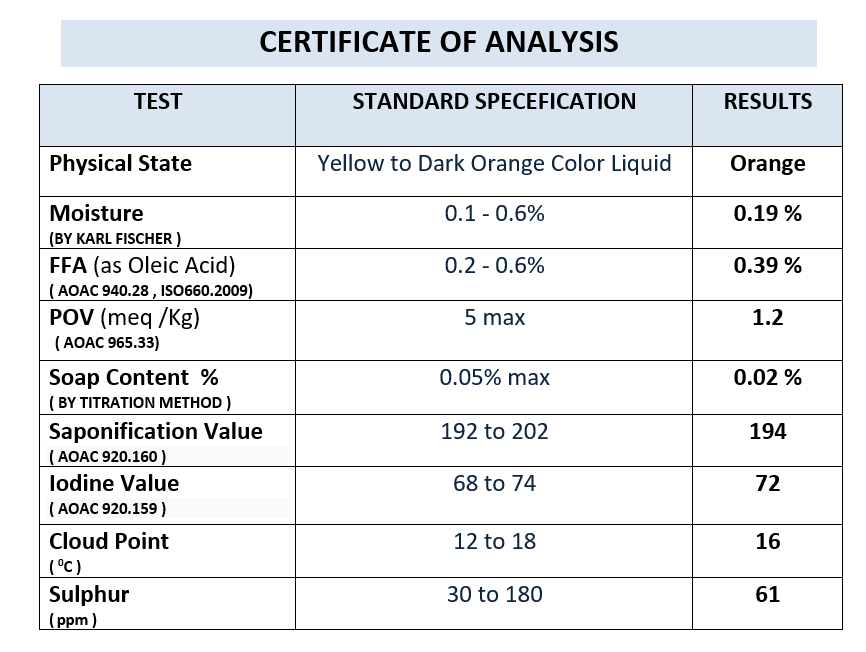

Poultry Fat

Poultry Fat is primarily obtained from the tissue of poultry in the commercial process of rendering or extracting. Poultry Fat is the component remaining after solids and moisture has been extracted in the normal rendering process. This finished product is used as an ingredient in the animal feed industry, detergents and soaps, cosmetics and recently in the biofuel segment.

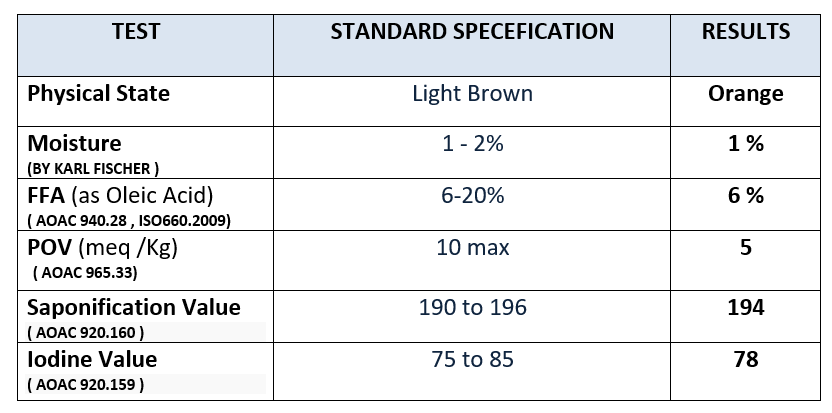

REFINE OIL

BY processing we can convert the crude oil into refine oil.

Chicken/Poultry Refine Oil is obtained from Crude Chicken Fat/Oil treatment, which produce from Rendering process of Poultry waste. Rendered Poultry/Chicken Oil is noted for being high value in linoleic acid and Omega-6 fatty acid. Linoleic acid levels are between 17 % and 22.8%. It is often used in animals and birds Feed; Other uses are Biodiesel and soap Industry. Poultry Crude Oil conversion to Refine Chicken Oil involves Steps:

Degumming

Caustic Stripping

Soap Removing

Bleaching & Filtering with activated Clay

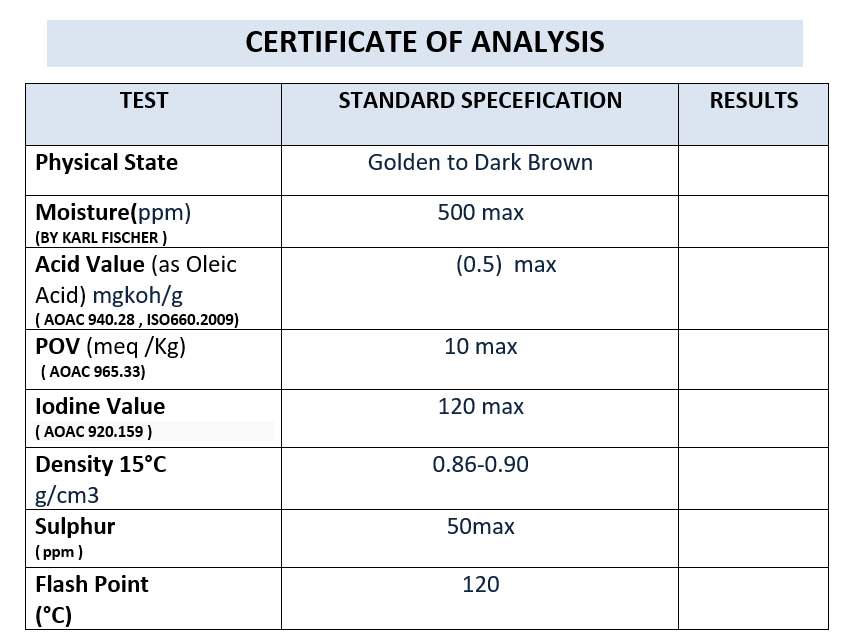

BIO DIESEL(EN14214)

- Biodiesel (FAME; Fatty Acid Methyl Ester) and renewable diesel (HVO; Hydrotreated Vegetable Oil) are renewable alternatives to fossil-derived diesel fuel. They are produced from an array of renewable feedstocks including rapeseed oil, used cooking oils (UCOs) and animal fats. Although often made from identical feedstocks, the processes used to make FAME and HVO are different, with different end uses.

- FAME is produced via biomass esterification, where fats are broken down then reacted with methanol to produce a final product similar to fossil diesel, but with a higher oxygen content. Like conventional diesel, biodiesel must comply with a CEN standard, EN14214. This ensures a standard quality and performance when FAME is used in a diesel engine, whether as pure biodiesel or as a part of a diesel/biodiesel blend. EU engine manufacturers have performed tests on blends with 5 to 10% biodiesel, 25 to 30% biodiesel, and with 100% pure biodiesel, resulting in guarantees for each blend.

GLYCERIN

Glycerin (Glycerol) is a simple polyol compound. It is almost colorless and a scentless, vicious liquid.

Being able to be produced from several other processes and feedstocks, glycerin is also a by-product in the biodiesel manufacturing process. Production of biodiesel in today’s time is through catalyzed reaction and this very reaction splits the oil into biodiesel and glycerin. For every 100 pounds of biodiesel produced approximately 10 pounds of crude glycerin is created.

Moreover, is a product of outstanding utility such as, possessing antiviral property, it is widely used in FDA approved wound and burn treatments and also as a sweetener in the food industry.

Making it more favorable, it is virtually non- toxic to the environment.

Read more

Acid Oil

Acid oil, which is a by-product in vegetable oil refining, mainly contains free fatty acids (FFAs) and acylglycerols, and is a candidate of materials for production of biodiesel fuel.

For removal of free fatty acids, vegetable oil refining traditionally consists of an alkali treatment step followed by vacuum distillation (“deodorization”). This renders as byproducts acid oils and deodistillates. Such type of refining is often referred to as chemical refining.

Acid oils from chemical refining “Product obtained during the deacidification of oils and fats of vegetable or animal origin by means of alkali, followed by an acidulation with subsequent separation of the aqueous phase, containing free fatty acids, oils or fats and natural components of seeds, fruits or animal tissues such as mono- and diglycerides, lecithin and fibers

BIO HEATING AGENT/TAR

The heavier component produced during the distillation process is ‘bio heating agent’. This has credentials as a renewable fuel oil that can be used in various boiler applications both onsite and externally. This reduces the environmental impact of the manufacturing process.